Product Description

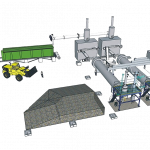

| Machinery Description: | _ Entry of the mixture in a horizontal reactor with stirrer (0.5 – 4.0 rpm)

_ Process temperatures <400 ° C _ Residence time 5-15 minutes _ Without pressure processing _ Independently controlled heating zones 2-4 _ Gas calming zone in the discharge of the reactor for the separation of the produced gas and the solid components (catalyst, coal dust). |

| Process characteristics | _ catalytic oiling

_ Pressure-free pulping process _ Relatively low temperatures (<400 ° C) _ Continuous process, not a batch furnace _ Material entry up to 1000 kg / h _ Production: 400-800 liters per ton of material entry, depending on the type (rubber, plastic) and quality of the input material and the catalyst. |

| Material storage and dosage | _ Dry storage of material to be entered

_ Feedstock from shredder Material Size 0-20mm _ Feedstock Moisture <10%, better <5%. _ Hopper with agitator to prevent bridging _ Discharge with exposed screw conveyor and gravimetric dosing unit _ Transport for the pretreatment means of conveyor belts _ Metal cutter |

| Machinery description | _ Entry of the mixture in a horizontal reactor with stirrer (0.5 – 4.0 rpm)

_ Process temperatures <400 ° C _ Residence time 5-15 minutes _ Without pressure processing _ Independently controlled heating zones 2-4 _ Gas calming zone in the discharge of the reactor for the separation of the produced gas and the solid components (catalyst, coal dust). |

| Maintenance | _ Every year overhaul (20 AT).

_ Cutting blade extruder. _ Interior reactor (bearing agitator and wear) _ Cleaning the condenser. _ Review of all moving parts. |

| Condensation | _ Atmospheric condensing of oil vapor.

_ No fractionation. _ Standing tube condenser _ water-cooled _ Mixture of Nafta, kerosene, diesel, light fuel oil _ Permanent gas are fed to the CHP (methane, butane, propane, heating value of about 3500 MJ / kg) |

| Water separation | _ For the separation of oil and water

_ Up to 10% water, depending on the material moisture when introduced into the reactor. _ Before de-watering, the oil is filtered. _ Before the product will be used in the CHP unit, a further filtering is necessary to minimize any possible constipation of the injectors. |

| Heat and electricity | _ CHP 500 kW (for a the single Reactor)

_ Fuel consumption (without addition of gas) about 60-70 l / h at 1000 kg / h material entry. By using the permanent gas 20-40% less. _ Fuel for CHP its own oil and gas production. _ Use of waste heat after return from the reactor for the drying of the feed stock, heating, hot water production, refrigeration |

| Pretreatment | _ Entry into a twin-screw extruder for densification of the material and expulsion of air.

_ Compacting of about 0.4-0.6 t / m3 at 1-1.2 t / m3 _ Pre-eating of the material. _ After the extruder, the compacted material is milled again. |

| Catalyst addition | _ Powdered aluminum oxide 99% alpha-alumina

_ gravimetric dosing _ Entry in 1-5% weight fraction based on material entry _ Alternative catalysts constantly tested (zeolites, nickel / molybdenum and others) _ It can be mixed with recycled Kat material and thus supplied to the process |

Reviews

There are no reviews yet.